John Deere約翰迪爾強(qiáng)鹿柴油機(jī)活塞和連桿的拆裝技術(shù)手冊

詳細(xì)描述

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)活塞和連桿的拆裝技術(shù)手冊

Remove Pistons and Connecting Rods

If engine is to be removed from the machine, see yourmachine technical manual.

CAUTION: Do not drain engine coolant until itcools below operating temperature. Then slowlyloosen block drain valve to relieve any

pressure.

1. Drain coolant and engine oil.

NOTE: If engine is to be completely disassembled, seeENGINE DISASSEMBLY SEQUENCE in Group010.

2. Remove cylinder head. (See REMOVE CYLINDERHEAD in Group 020 for two valve head or REMOVECYLINDER HEAD in Group 21 for four valve head.)

3. Remove camshaft followers and keep in order forreassembly in same position.

4. Clean all foreign material from cylinder block top deck.

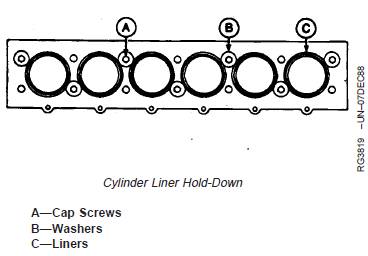

IMPORTANT: Cap screws and washers must betightened to the correct specification toachieve an accurate reading whenchecking liner standout (height aboveblock), as detailed later in this group.

5. Use short cap screws (A) and 3 mm (1/8 in.) thickwashers (B) to bolt down cylinder liners (C). Fasteneach liner in two locations. Tighten cap screws to 68

N•m (50 lb-ft).

NOTE: Do not rotate crankshaft with cylinder headremoved unless liners are fastened down.

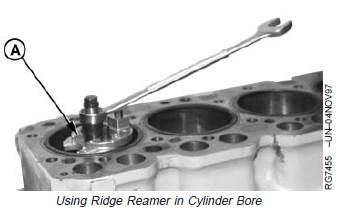

NOTE: Always follow manufacturer’s directions providedwith ridge reamer.

6. Remove carbon from liner bore with a scraper or ridgereamer (A). Use compressed air to remove loosematerial from cylinders.

7. Remove oil pan, oil pump, and pick-up tube. (SeeREMOVE, INSPECT AND INSTALL OIL PUMPPICK-UP TUBE ASSEMBLY in Group 060.) (SeeREMOVE ENGINE OIL PUMP in Group 060.)

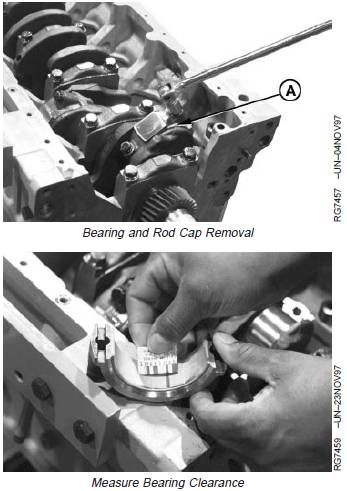

8. Mark rods, pistons, and caps to ensure correctassembly in same location.

IMPORTANT: Keep inserts with their respective capsfor rod and main bearings.

9. Remove all rod caps (A) with bearings.

10. Measure rod bearing-to-journal oil clearance withPLASTIGAGEâ before removing piston and rodassembly. Record measurements. (See INSPECTAND MEASURE CONNECTING ROD BEARINGS,later in this group.)

NOTE: Use PLASTIGAGEâ as directed by themanufacturer. PLASTIGAGEâ will determinebearing-to-journal oil clearance, but will notindicate the condition of either surface.

A—Rod Caps

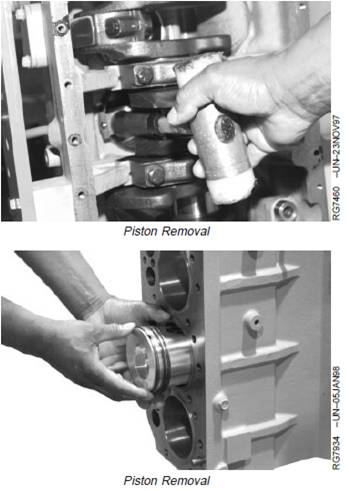

IMPORTANT: Hold onto piston to prevent piston fromdropping. Piston will drop once pistonrings have cleared cylinder liner.If liners are to be reused, be extremelycareful not to let connecting rod hitliner bore when removing piston androd assembly.

11. Gently tap piston through top of cylinder block fromthe bottom.

12. Remove pistons and rods from engine.

13. If piston rings are to be reused, measure piston ringend gap and compare to the following specifications:Piston Rings—4045DF, TF150 and 6068DF, TF150 Engines —Specification

No. 1 Compression—End Gap ........... 0.33—0.58 mm (0.013—0.023 in.)

No. 2 Compression—End Gap ........... 1.24—1.49 mm (0.049—0.059 in.)

No. 3 Oil Control—End Gap ............... 0.30—0.56 mm (0.011—0.022 in.)

Piston Rings—4045TF250 and 6068TF250 Engines—Specification

No. 1 Compression—End Gap ........... 0.33—0.64 mm (0.013—0.025 in.)

No. 2 Compression—End Gap ........... 0.75—1.00 mm (0.030—0.039 in.)

No. 3 Oil Control—End Gap ............... 0.33—0.64 mm (0.013—0.025 in.)

Heavy Duty Piston Rings—Specification

No. 1 Compression—End Gap ........... 0.33—0.59 mm (0.013—0.023 in.)

No. 2 Compression—End Gap ........... 0.89—1.14 mm (0.035—0.049 in.)

No. 3 Oil Control—End Gap ............... 0.33—0.59 mm (0.013—0.023 in.)

14. Remove all main bearing caps with bearings. Removecrankshaft from engine.

400-100-8969???15088860848

0574-26871589? 15267810868

0574-26886646? 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(簡)

中文(簡) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska